- Beschreibung

-

Details

LED line lamp socket S14 - Contact problems - Fixing problems

Contact problematic line lamps S14 due to poor mounting

Attached you will find some information about possible contact problems, or inadequate mounting of LED line lamps with the socket S14.

The following products may be affected by the following manufacturers: OSRAM / Philips / RZB / Radium ...

History:

Some product manufacturers have made use of the note in your product catalog: "Technical changes reserved". The following is an excerpt from the manufacturer's correspondence.

The new socket for the S4 line lamp has been carefully tested before the introduction.

The new socket complies with all standard requirements for S4 sockets.

In addition, sample lamps with the modified base were tested in numerous frames and luminaires commonly used in the market.

With the multitude of internationally available different systems, however, it was clear that the product manufacturers could not possibly test all the fixtures and fixtures (of which they often have no knowledge).

Here is an example of a photo for illustrative purposes

New (plastic) and old (brass) basePossible solutions:

(Please only be carried out by qualified personnel and set the system without electricity)

Professional Solutions:

- Replacement of base S14

- Replacement of the light strip

Common "home improvement" solutions:

(See disclaimer)

- bending of the retaining springs

- Wrap the base of the line lamp sideways with an insulating tape around the clamping surface to enlarge

- Apply heat shrink tubing to the base of the line lamp to increase the clamping area.

The changes can be so different (customer picture)Many customers have used old-fashioned lamp-lampholders, which have a metal border.

Here one can almost assume that one will get contact problems or fixing problems.Contact problematic line lamps S14 causes the pressure switch of the light strip

(-> the line lamp makes a belly in the middle or jumps out)

Common "home improvement" solutions:

(See disclaimer)

Some manufacturers of line lamp sockets (light strips) have a push button in the middle of the base which serves to switch the contacts without electricity when the line lamp is removed.If the line lamps (mostly length with 1000mm) have not been designed to be stable enough, the push button pushes the line lamp upwards in the middle.

This causes the button, if any, to protrude so far that the voltage disconnection of the light strip is given. That is, They have no current on the contacts and the line lamp does not light up.

If you press the center of the lamp with your finger in the middle and the lamp is lit again, this is usually the cause.Common "home improvement" solutions:

(See disclaimer)

- Attach adhesive tape around the push button

- mechanical clamping of the push button

- use a hot glue gun or a 2K glue to secure the push button

- Glue the adhesive tape transparently over the light strip and the line lamp to fix it

Currently we have this problem mostly with the manufacturer RZB, in combination the RZB light strip 1000mm as well as the RZB line lamp with 1000mm length type: 10-2333.

Here, as a rule, the line lamp can jump out of the socket by the tension of the push button.

We are currently working on a solution to this problem.Contact problematic line lamps S14 due to corrosion in the base

Main features: bathroom, baths, damp rooms, cellar

Line lamps S14, which are usually installed for many years, have corrosion on the contact surfaces / contact pins of the sockets over time due to the increased humidity in damp areas.

After expanding the old line lamp and replacing it with a new LED bulb (for example, LED line lamps with base S14d or S14s), customers usually have contact problems such as flickering etc.

The customer usually complains the line lamp as a defect at the dealer.

Comprehensible customer argument: "If I incorporate the original line lamp works this, the LED line lamp does not light, so this is broken."

This is often due to the fact that the "normal" line lamp is e.g. 100cm / 1000mm has a current consumption of mostly 120 watts.

As a result of the high power consumption, the contacts or contact surfaces may burn out again.

The LED line lamp usually requires the 80% less current than the "classic line lamp.

This lower current consumption usually leads to this:

A) there is no contact at all, since the current is not sufficient to "free" the contacts again,

B) the LED line lamps only flicker

C) the LED light is only lit when you lightly press it into the socket

D) light up the LED lamps only briefly and then go out again as they slip out of the socketIs my LED line lamp broken or ok?

Functional check LED lamp with socket S14 .. how?

How can I check my LED lamp myself if I do not have a new matching socket available?

Again, we must give the legal advice that such measures should only be carried out by authorized specialists.

If you have nevertheless decided to carry out the test yourself, you can quickly check the LED line lamps for function:

Socket S14s (line lamp with left and right socket)

230V / AC from the socket

L (phase) on one base.

N (neutral conductor) to the other socket.

It is not critical whether L (phase) + N (neutral) is applied to the left or right.PROOF WITH 230 Volt / AC

If the LED light is on, it is OK.

If the LED line lamp is not lights, this is defective.

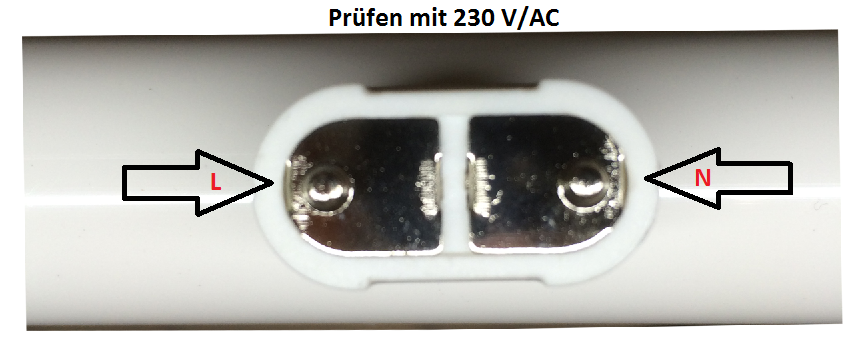

Socket S14d (line lamp with a base in the middle)

The base S14d has the current consumption for L (phase) and N (neutral) in a base.

The base is located in the center of the line lamp.

L (phase) to the left contact of the base.

N (neutral conductor) to the right contact of the socket.

It is not critical whether L (phase) + N (neutral) is applied to the left or right of the contact pad.Proof with 230V / AC

If the LED light is on, it is OK.

If the LED line lamp is not lights, this is defective.The LED line lamps do not need a ballast or starter devices!

Disclaimer of liability:

The author reserves the right not to be responsible for the topicality, correctness, completeness or quality of the information provided. Liability claims against the author, which relate to damages of material or ideal kind, caused by the use or non-use of the presented information or by the use of incorrect or incomplete information, are in principle excluded, as long as the author is not demonstrable or grossly negligent Fault is present. - Zusatzinformation

-

Zusatzinformation

Artikelklasse FAQ Artikelnummer FAQ-EN-Linienlampen_Line Lamp Kurzbeschreibung FAQ English - Line Lamps

Beschreibung 1 LED line lamp socket S14 - Contact problems - Fixing problems

Contact problematic line lamps S14 due to poor mounting

Attached you will find some information about possible contact problems, or inadequate mounting of LED line lamps with the socket S14.

The following products may be affected by the following manufacturers: OSRAM / Philips / RZB / Radium ...

History:

Some product manufacturers have made use of the note in your product catalog: "Technical changes reserved". The following is an excerpt from the manufacturer's correspondence.

The new socket for the S4 line lamp has been carefully tested before the introduction.

The new socket complies with all standard requirements for S4 sockets.

In addition, sample lamps with the modified base were tested in numerous frames and luminaires commonly used in the market.

With the multitude of internationally available different systems, however, it was clear that the product manufacturers could not possibly test all the fixtures and fixtures (of which they often have no knowledge).

Here is an example of a photo for illustrative purposes

New (plastic) and old (brass) basePossible solutions:

(Please only be carried out by qualified personnel and set the system without electricity)

Professional Solutions:

- Replacement of base S14

- Replacement of the light strip

Common "home improvement" solutions:

(See disclaimer)

- bending of the retaining springs

- Wrap the base of the line lamp sideways with an insulating tape around the clamping surface to enlarge

- Apply heat shrink tubing to the base of the line lamp to increase the clamping area.

The changes can be so different (customer picture)Many customers have used old-fashioned lamp-lampholders, which have a metal border.

Here one can almost assume that one will get contact problems or fixing problems.Contact problematic line lamps S14 causes the pressure switch of the light strip

(-> the line lamp makes a belly in the middle or jumps out)

Common "home improvement" solutions:

(See disclaimer)

Some manufacturers of line lamp sockets (light strips) have a push button in the middle of the base which serves to switch the contacts without electricity when the line lamp is removed.If the line lamps (mostly length with 1000mm) have not been designed to be stable enough, the push button pushes the line lamp upwards in the middle.

This causes the button, if any, to protrude so far that the voltage disconnection of the light strip is given. That is, They have no current on the contacts and the line lamp does not light up.

If you press the center of the lamp with your finger in the middle and the lamp is lit again, this is usually the cause.Common "home improvement" solutions:

(See disclaimer)

- Attach adhesive tape around the push button

- mechanical clamping of the push button

- use a hot glue gun or a 2K glue to secure the push button

- Glue the adhesive tape transparently over the light strip and the line lamp to fix it

Currently we have this problem mostly with the manufacturer RZB, in combination the RZB light strip 1000mm as well as the RZB line lamp with 1000mm length type: 10-2333.

Here, as a rule, the line lamp can jump out of the socket by the tension of the push button.

We are currently working on a solution to this problem.Contact problematic line lamps S14 due to corrosion in the base

Main features: bathroom, baths, damp rooms, cellar

Line lamps S14, which are usually installed for many years, have corrosion on the contact surfaces / contact pins of the sockets over time due to the increased humidity in damp areas.

After expanding the old line lamp and replacing it with a new LED bulb (for example, LED line lamps with base S14d or S14s), customers usually have contact problems such as flickering etc.

The customer usually complains the line lamp as a defect at the dealer.

Comprehensible customer argument: "If I incorporate the original line lamp works this, the LED line lamp does not light, so this is broken."

This is often due to the fact that the "normal" line lamp is e.g. 100cm / 1000mm has a current consumption of mostly 120 watts.

As a result of the high power consumption, the contacts or contact surfaces may burn out again.

The LED line lamp usually requires the 80% less current than the "classic line lamp.

This lower current consumption usually leads to this:

A) there is no contact at all, since the current is not sufficient to "free" the contacts again,

B) the LED line lamps only flicker

C) the LED light is only lit when you lightly press it into the socket

D) light up the LED lamps only briefly and then go out again as they slip out of the socketIs my LED line lamp broken or ok?

Functional check LED lamp with socket S14 .. how?

How can I check my LED lamp myself if I do not have a new matching socket available?

Again, we must give the legal advice that such measures should only be carried out by authorized specialists.

If you have nevertheless decided to carry out the test yourself, you can quickly check the LED line lamps for function:

Socket S14s (line lamp with left and right socket)

230V / AC from the socket

L (phase) on one base.

N (neutral conductor) to the other socket.

It is not critical whether L (phase) + N (neutral) is applied to the left or right.PROOF WITH 230 Volt / AC

If the LED light is on, it is OK.

If the LED line lamp is not lights, this is defective.

Socket S14d (line lamp with a base in the middle)

The base S14d has the current consumption for L (phase) and N (neutral) in a base.

The base is located in the center of the line lamp.

L (phase) to the left contact of the base.

N (neutral conductor) to the right contact of the socket.

It is not critical whether L (phase) + N (neutral) is applied to the left or right of the contact pad.Proof with 230V / AC

If the LED light is on, it is OK.

If the LED line lamp is not lights, this is defective.The LED line lamps do not need a ballast or starter devices!

Disclaimer of liability:

The author reserves the right not to be responsible for the topicality, correctness, completeness or quality of the information provided. Liability claims against the author, which relate to damages of material or ideal kind, caused by the use or non-use of the presented information or by the use of incorrect or incomplete information, are in principle excluded, as long as the author is not demonstrable or grossly negligent Fault is present.[Garantie Jahre] keine Information - Bewertungen

-

- Downloads

-

Keine Informationen.

Herzlich willkommen bei SPECIAL-LED - jetzt professionell auf LED umsteigen

Menü

Suche

Benutzerkonto

Warenkorb

0

Kürzlich hinzugefügte Artikel ×

Sie haben keine Artikel im Warenkorb.